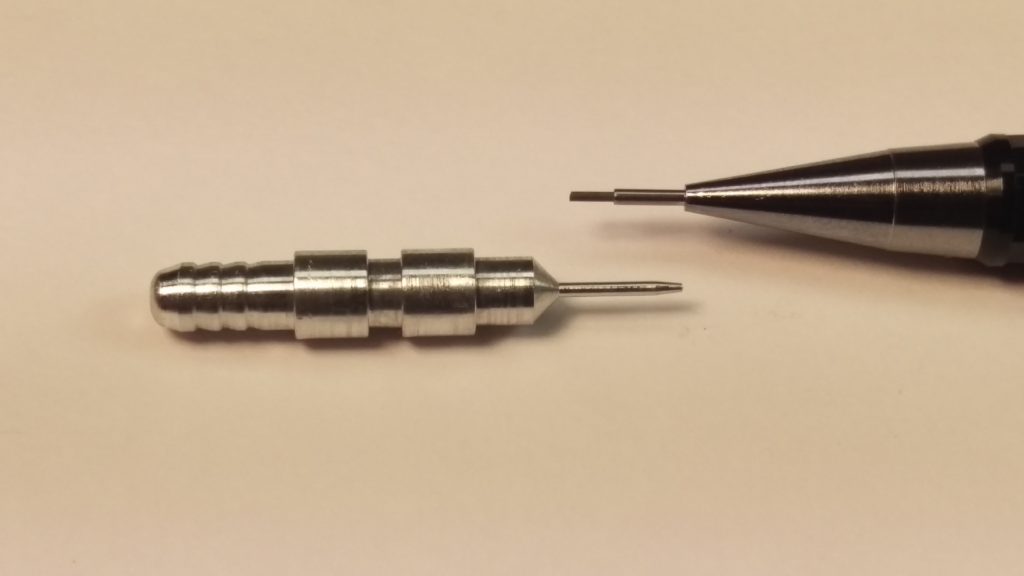

High Voltage Terminals

Many of our clients can’t afford rigid processes or long lead times. MS&J Screw Products understands this, and we strive to provide quick, competitive quotes for our fast and effective services. All of our operations are supported by a dedication to quality and continuous improvement from every member of our team. Our ISO 9001:2015–certified facilities feature state-of-the-art equipment, NIST measuring and tracking, process capability studies, and capabilities to meet the most exacting tolerances available.

Many of our clients can’t afford rigid processes or long lead times. MS&J Screw Products understands this, and we strive to provide quick, competitive quotes for our fast and effective services. All of our operations are supported by a dedication to quality and continuous improvement from every member of our team. Our ISO 9001:2015–certified facilities feature state-of-the-art equipment, NIST measuring and tracking, process capability studies, and capabilities to meet the most exacting tolerances available.

The following case study from our project portfolio demonstrates our capabilities.

High Voltage Terminals Project Specifications

The client came to us requesting a solution that would address a significant challenge related to the production of high voltage terminals. These were the project specifications:

- Equipment: Davenport Screw Machines

- Tolerance: +/- .001

- Material: Aluminum 2011-T3

- Finish: 32

- Industry: Automotive Aftermarket

- Volume: 5 Million

- Cycle Time: 6 weeks/ delivering 100,000 pcs/week

- Locations: USA & Poland

Project Highlights

This was an unusual challenge that most Davenport shops would refuse to undertake because of the extensive and highly complex setup process required to meet the customer’s need. Since it was not a standard setup, our team had to think outside the box for our process to survive the challenges of this extended production run.

Why Was MS&J Chosen?

The client had used our services for less challenging projects in the past. They approached MS&J for this project because they were having a difficult time finding a shop with the capacity to handle the required volume and quality specifications while still maintaining a reasonable price point.

The Challenge

Our client needed a very delicate part with tight tolerances and precise dimensions. The part has a 0.020-inch diameter tip that is approximately 0.3 inches long with a required tolerance of +/- 0.001 inches. The timeframe required production of 5 million units within a 6 week period at a delivery rate of 100,000 pieces per week.

Project Results

MS&J Screw Machine met all client requests:

- We provided on-time delivery of 100,000 pieces each week for 6 weeks, fulfilling our commitment.

- The dimensional quality and tolerances met expectations.

- Our customer was well satisfied with the results and provided us with a great deal of positive feedback.

- We exceeded expectations and produced the part at a fraction of the cost they had provided for in their budget.

This case study is representative of the complex challenges MS&J Screw Machine solves on a consistent basis. Our advanced equipment, the creative abilities of our expert team, and our commitment to quality make it possible for us to provide solutions to any challenges our clients present.

We possess Davenport, New Britain, and CNC screw machines coupled with years of expertise in our trade. We dedicate ourselves to providing rapid, high-level service at competitive prices and have the capacity to manufacture components with precise tolerances at high production volumes with short cycle times.

Contact us or request a quote to learn more about MS&J Screw Products and how we can streamline your projects.